Open Integration Hub Platform

Embedded Integration Center as a Service

Focus your resources on your own solution and benefit from a ready-to-go Integration Center. Scale your product integrations 10x more effectively.

Start for free:

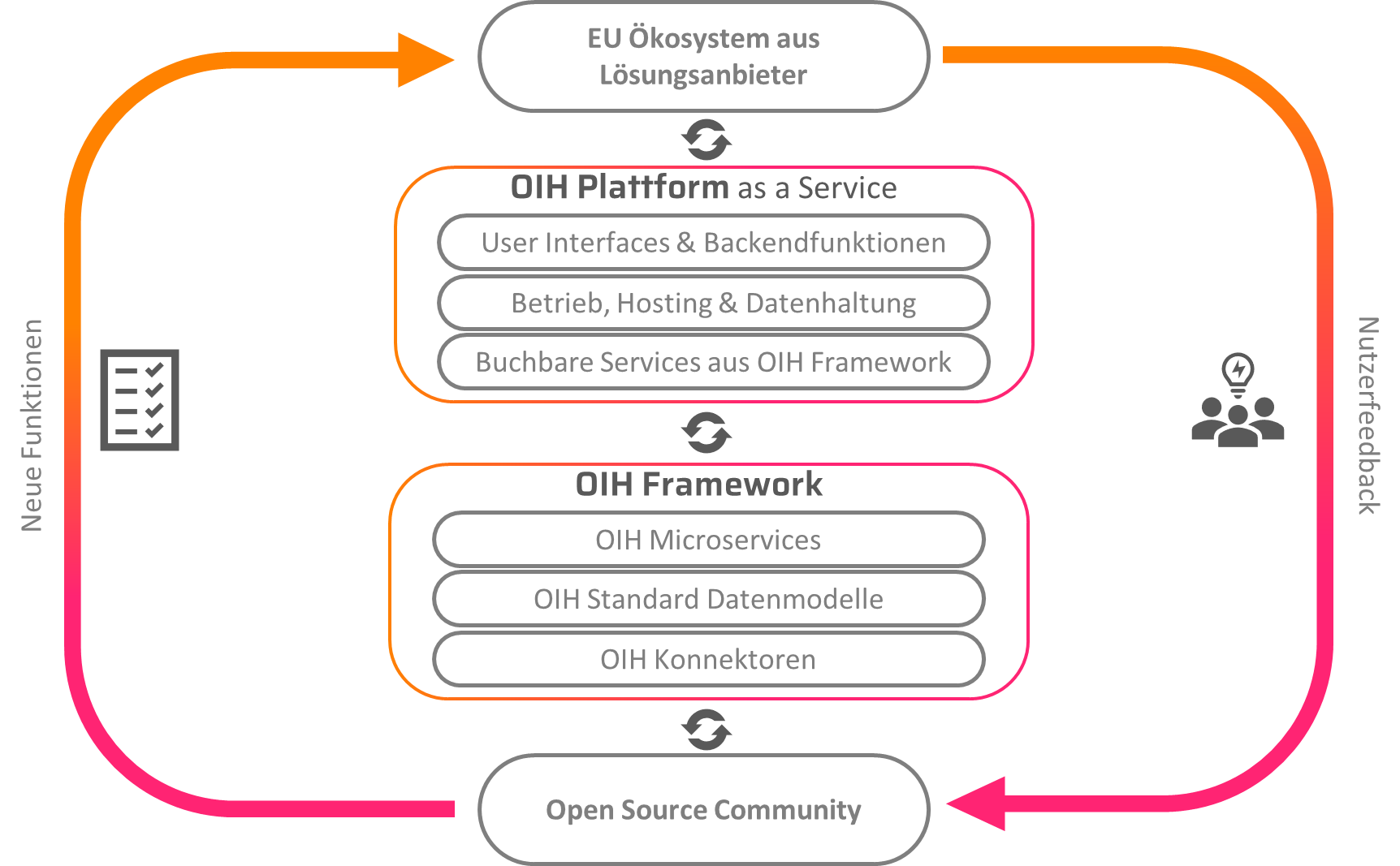

Open Integration Hub Framework

Manufacturer-neutral open source framework for easy data synchronisation between any choice of software applications. The Open Integration Hub is a framework made up of technology, standard data models, rulesets and a community of connectors. Depending on the requirements and business model, these components are used very differently.

Advantages of the hub model

You only need one connector to the hub instead of one connector for each application. This provides for reduced effort and outlay in development and maintenance. The standardisation achieved here creates a much higher level of process automation.

With the Open Integration Hub, Cloud Ecosystem has successfully developed technology, standards and concepts that allow companies to use data for business processes across applications and by doing so accelerate digitalisation.

Building on this basis, as well as on the positive response from the German business community, the focus of the Open Integration Hub is now being expanded to include medium-sized manufacturing companies.

The OIHplus project has been started for this purpose. The project is supported by BMWi and backed by several providers from the cloud community.

The digitalisation platform

The OIHplus project is developing an open digitalisation platform (OIH platform) to supports SMEs to overcome the typical challenges of digitalisation. Support is provided in meeting compliance requirements, intelligent, cross-system process management, and cross-vendor condition monitoring for production optimisation. These functions are based on the intelligent analyses of integrated and centrally available data. The Open Integration Hub project already provides the core functionalities for data integration and storage.

The main focus and topics:

1. Industrial data interoperability

The expansion to include manufacturing SMEs means that both machine data and production control are included. The comprehensive information available will enable smaller manufacturing companies to monitor the status of entire production lines for the first time, and not just individual pieces of equipment.

In particular, SMEs without any industrial IoT expertise will then be able to integrate their systems more easily and optimise production.

2. Data Intelligence

The central storage of data through the OIH framework provides an optimal source of data for analyses using intelligent processes. OIHplus provides data intelligence functions for processing data so it can be analysed using various AI systems.

The data intelligence functionality identifies usage patterns, for example as a basis for process optimisation.

3. Smart Processes

For process optimisation purposes, both workflows and dataflows and the use of applications are analysed anonymously based on peer groups (many companies in one industry).

This provides SMEs with automated suggestions for optimising their processes without the need for inhouse process expertise.

4. Governance

OIHplus supports SMEs in ensuring that compliance duties are fulfilled through standardised methods of smart governance. As a part of this, release mechanisms preserve data sovereignty and facilitate the exchange of data with third parties.

To this end, decentral federal concepts and architectures (e.g. Industrial Data Space (IDS) or SOLID (Social Linked Data)) are being investigated and implemented as prototypes for SMEs for the first time.

5. Process Management

Processes are not modelled precisely in advance, but are compiled individually from existing "process modules" for each business transaction and made available as a digital executable process model.

SMEs are to receive support in the analysis, monitoring and control of the processes. Process optimisation suggestions are made to the SME for this purpose over the "Smart Process Assistance". Smart Process Assistance is based on suitable KPI systems, data mining and AI methods, as well as their parameterisation.

6. Transfer to science

Our scientific partners, the Fraunhofer IAIS and the Hochschule Bonn-Rhein-Sieg, University of Applied Sciences, will through publications and other supporting measures, make a significant contribution to the dissemination of the OIHplus project in the scientific community.

The ecosystem also aims to cooperate with associations and scientific institutions in order to disseminate the project results and is actively supported in doing so by the IAIS.

Our Partners

Contact

We look forward to receiving your feedback, queries and ideas. Contact us today! We will get back in touch with you as quickly as possible.

Veerle Türling

Head of Marketing

Use the form or the contact information below to get in touch with us.

*The data we collect here is only used for initial contact purposes.

veerle.tuerling@cloudecosystem.org